If you want to improve workflow in a production print environment, in-line operations should be first on your list for research. By automating these operations in workflows you will reduce total production time; thereby, shortening turn times and reducing labor costs as opposed to off-line manual operations.

Most production systems come standard with some capabilities to automate operations and offer an assortment of options to fit more specialized applications. You will typically find the ability to print on standard tab extensions and insert them as divider pages in manuals. Pre-cut blank tab sets come in a wide array of tab sizes to fit your needs and are available pre-collated to run through production devices. When you combine this with in-line punching capabilities you can produce book blocks ready for final binding. A simple way to improve workflows is with job presets which are typically found in standard print drivers and optional controllers. Presets will save set up time and cut misprint waste by storing the appropriate settings for a print job and then applying them to other jobs with the same requirements.

The real powerhouse workflow improvements are found in optional equipment and the operations they perform. The following are some examples of in-line options and how they can be used to improve your workflows.

If you need to produce saddle style booklets or simple fold in half sheets, you should consider a booklet finisher rather than a simple flat sheet staple finisher. Most manufactures offer a finisher like this for production devices and may also work with aftermarket providers for finishers with greater capabilities. If you choose this type of finisher consider the following.

• How many sheets will it staple

• What paper weights will it handle

• What paper sizes will it handle

• What options are available

Options may be available to trim the open side (known as the face) of the booklet or the top, bottom, and face (known as three side trim). Extended conveyors to allow easier gathering of finished product and options to square the spine to mimic a perfect bound book may also be available on some devices.

To improve GBC binding workflows, many production devices are compatible with a GBC stream punch to provide in-line punching with changeable dies to match the binding system(s) that you use. Complete book blocks can be produced that are ready for one of the five styles of GBC binding or insertion into three ring binders.

Folding units provide common styles of folding without the manual handling, time, and labor involved in folding offline. Typically you will find the ability to produce letter folds in and out, half folds, double parallel, gate and z folds ready to use directly from the device.

Interposers provide the ability to insert covers or sheets into the finished product post engine, thereby avoiding the imaging counter, rollers and plates in the paper path, and imaging processes. Covers and inserts are often produced by other methods and may bring properties with them that cause issues when ran through the engine. There are many reasons why you may want to utilize this option and the following are the most common.

• Avoid hand collating covers and/or special sheets into the product

• Utilize downstream features like punching for covers and/or special sheets

• Prevent damage to engine from covers containing metallic images or special coatings

• Avoid the click charge that happens with each sheet through the engine

• Prevent damage to the cover or sheet from the fusing process

Stacker units facilitate wheeled carts to make completed flat sheet products easy to move and eliminate the manual offloading of finished products from the device. For long runs a second stacker can be utilized to keep production rolling while the first unit is emptied and prepared with another empty cart.

Optional print controllers, like models from Fiery and Creo, offer diverse workflow tools to pre-flight jobs and optimize run time by capitalizing on pre-ripped files being queued for production or moved between devices. These controllers also enhance print-on-demand capabilities by having the file ready to run again with minimal setup or file ripping.

Whether you add options or use the embedded capabilities of a production device you can dramatically cut cost, waste, and turn times while producing better products from improved workflows in your organization.

Topics: Production Print, Process Improvement, Ricoh, #CustomerServiceExcellence, #MoreThanPrint, #MoreThanCopiers, #ManagedPrintServices, sustainability, improve profits, Workflows

The lowest cost per copy or page is probably not your best buying criteria.

Let’s first address the factors which determine a cost per copied or printed page and in order to do this let’s assume an average monthly volume of 5,000 pages.

In a true cost per page, the equipment would be included. If the cost of the equipment is the industry average, $6,500, and is leased for five years this should be approximately $130 per month. At 5,000 pages per month, you will need $.026 per page just to cover the equipment cost.

Toner is a huge factor in determining cost per page. Our example above is a color device. This means it will require four toners at a time: Black, Cyan, Magenta and Yellow. Let’s assume the price for a black toner is $79 and yields approximately 16,500 pages based on 5% coverage. This would make just the black toner $.0048 per page.

The Cyan, Magenta and Yellow toners each cost $120 and yield approximately 5,500 pages based on 5% coverage. Each color toner costs $.022

A Full Color Page is calculated at 20% coverage of the page and based on these numbers, would equate to approximately $.07 just in toner costs.

Now, I am going to throw a wrench out, not to get us sidetracked, but it is something that definitely needs to be addressed. What happens when you want to have an extra set of toners on the shelf but you are only paying a cost per page price?

Toners on the shelf are not actually generating any cost per page revenue for your vendor. In the scenario above, this would equate to $439 in additional costs not factored into the cost per page. In essence, the cost per page for black just doubled to $.0096 per page and $.14 for a full color page just for toner. While there is the argument of having extra toner so you never run out and experience downtime, the fact is the number one cause of running out of toner is human error. The technology today is so advanced, if you sign up for our AutoTech program, you will never need those additional toners on the shelf nor need to worry about human error. You can read more about AutoTech,

Other consumable items would include the following:

Photoconductor or Development Units are often referred to as drums. In a color device, there will also be four of these units: Black, Cyan, Magenta and Yellow. They often range from $100 - $200 each.

Transfer Belts are also in the $100 - $200 range, as are Fusing Units or Fusers and Exhaust Filters.

Topics: Managed Print Services, Business Improvement, Printing, Faxing, Copier Pricing, Pricing, Copier Issues, Process Improvement, Copier Service, Document Management, Net Promoter Score, Customer Satisfaction, NPS, MPS, Response Time, Repair Time, Printer Service, Office Equipment Buying Guide, Printer Pricing, Copier RFP, Office Equipment Criteria, Cost Per Copy, Cost Per Page

Managed Print Service: Award Winning Collaborations

Doing Better Business began creating custom Printer Fleet Management programs in 2004 to help our clients measure, right-size, optimize, manage and constantly work towards improving business processes with the main emphasis on continual evolution towards a more paperless office.

Topics: Managed Print Services, Business Improvement, Printing, Industry Trends, Faxing, Awards, Process Improvement, Customer Service, Copier Service, Document Management, Customer Satisfaction, MPS, Customer Service Excellence, Printer Service, Ricoh Service, Copier RFP

5 Best Practices to Prevent Issues During Delivery & Installation

Replacing or adding a Multifunction Copier/Printer should be seamless if the proper steps are taken before scheduling the delivery.

Topics: Printing, Copier Pricing, Copier Problems, Pricing, Copier Issues, Process Improvement, Copier Service, Printer Service, Ricoh Service, Sharp Service, Canon Service, Savin Service, HP service, Lanier service, Good Service, Xerox Service, Toshiba Service, Kyocera service, Office Equipment Buying Guide, Office Equipment Purchase, Printer Pricing, Office Equipment Criteria

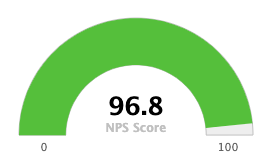

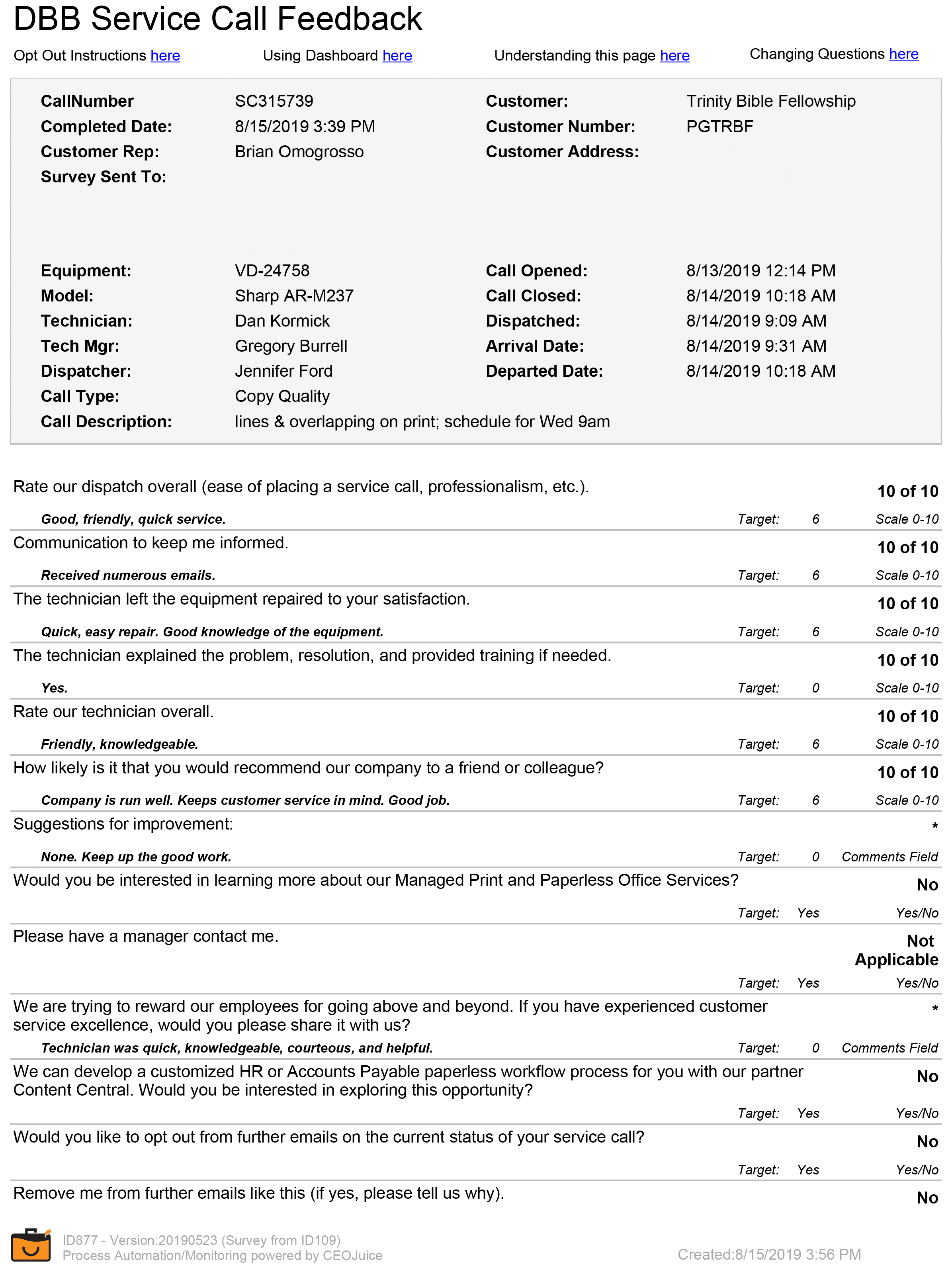

NPS is a critical factor when choosing a managed print services or traditional office equipment provider

NPS stands for Net Promoter Score which is a metric used in customer experience programs. NPS measures the loyalty of customers to a company. NPS scores are administered by a third, unbiased party with customer satisfaction surveys and reported with a number from -100 to +100, a higher score is desirable.

Topics: Managed Print Services, Business Improvement, Industry Trends, Process Improvement, Survey, Customer Service, Copier Service, #lovemytech, Net Promoter Score, Customer Satisfaction, NPS, MPS, Response Time, Repair Time, Customer Service Excellence

Do I have to fill out a survey every time?

Topics: Process Improvement, Survey, Emails, Customer Service