If you are looking for an article about collectible paper weights, this is not it. This article is about understanding the terminology behind copier and printer paper weights. In researching this article, I did find the Paperweight Collector's Association at paperweight.org.

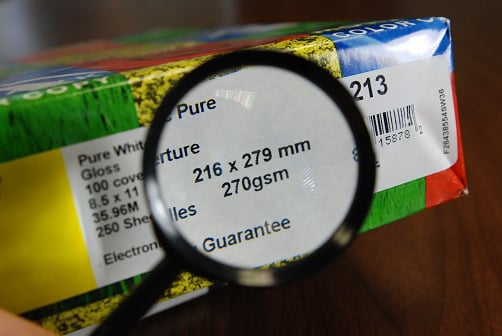

The adoption of gsm or grams per square meter standard, as a weight measurement system for paper in the United States, has greatly simplified the identification and proper use of various papers. The gsm is often found on the ream wrapper label and may also appear with the mathematical formula g/m2 instead of the acronym. Making it easy to understand, the gsm number has a direct correlation to real weight of the paper.

The traditional U.S. basis weight standard is still used by many as part of the description of paper; however, you must either memorize conversions or use a chart to decipher the relative weight. To illustrate the difficulty of understanding the basis weight system, consider that 20 lb. bond paper is actually equal to 50 lb. text or book paper. At two and a half times the weight for basically the same paper, you can understand what I’m talking about.

The wide range of weights used in the description are due to how the weight is calculated in the basis weight system. In our previous example, the 20 lb. bond paper was calculated by using 500 sheets of 17” x 22” basis sized paper. All bond paper is measured with this size basis sheet and all papers are weighed with 500 sheets of the basis size. Text or book paper is weighed with a basis sheet measuring 25” x 38”. So you can see that the variation of the basis sheet affects the basis weight, thereby making it hard to understand.

The paper weight plays into many aspects of producing a printed product. To start, you can decide which paper weight may be best for a particular use. The most common paper used in the office environment is 20 lb. bond which is 75 gsm. This weight of paper is good for general documents but a heavier paper like 67 lb. vellum at 147 gsm or 65 lb. cover at 176 gsm would be more appropriate for brochures and specification sheets. For business cards, you may want to consider 100 lb. cover at 270 gsm or even higher if you have the ability to image this heavy paper.

If you plan to image a project yourself, you will probably be using a digital device with toner or ink. When printing with a digital device there are two major issues with paper weight: getting the paper to feed through the device and getting the toner to fuse, or ink to adhere, to the paper. If the paper weight doesn't fit within the specifications of the device, the finished product may not be what you expected.

Once you know you are working within the specifications of the printing device, you need to use the correct drawer or bypass on the device. Not all drawers or paper trays are created equal, be sure to check the device specifications. A good rule of thumb for heavy paper is to use the tray that has the straightest path into the device. Less bending and turning is a good thing.

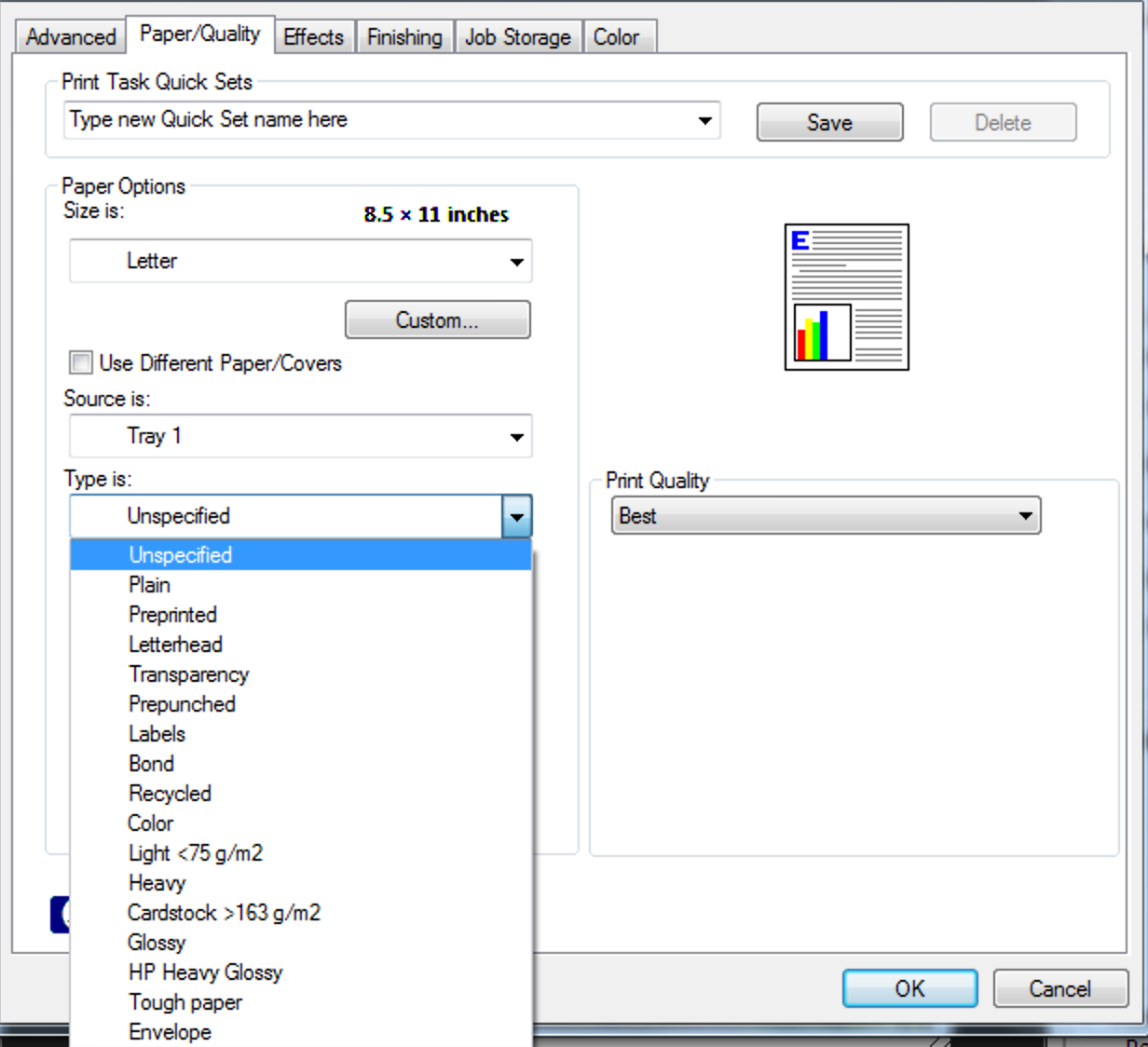

Now, for the real important stuff, you have to communicate with the device as to what the weight and sometimes the type of paper you are using, like coated vs. plain. You communicate with the device via the print driver. This is done in different ways depending on the manufacturer. Some devices require settings on the device and in your print driver, others only in the driver. Consult your manuals or supplier for help.

The correct settings help ensure proper feed through the device and set the temperature for good image fusing to the paper. Toner must be melted at the correct temperature to fuse correctly. Heavy paper basically sucks up the heat and can cause poor fusing if not corrected. The symptom of not enough heat is toner not sticking to the paper in the image area, thus allowing it to transfer to rollers and then tracking to other areas on the sheet. Too much heat creates its own issues, so don’t use a heavy setting for everything. With knowing a little more about paper weight and settings, I hope everyone can produce great printed pieces every time.

Contact a representative from Doing Better Business if you would like more information on the perfect device and paper to print your next project.